Explore Wescan Construction Services’ Millwright Solutions. We provide services to ensure efficient machinery operations for commercial and industrial facilities. Our range of services covers seamless installation, careful maintenance, and fine-tuning for a wide variety of equipment. With a focus on precision and reliability, we help businesses achieve optimal performance and efficiency, save time and money, across many market sectors. Wescan’s Millwright Division was implemented to offer our clients further service to help meet their needs, and to make sure that their down time is minimal.

Regular maintenance is crucial for the optimal functioning of industrial machinery. Our Millwrights perform routine inspections, lubrication, and adjustments to prevent breakdowns and extend equipment lifespan.

Our team has the expertise necessary to identify and rectify issues with machinery, employing diagnostic tools and techniques to pinpoint problems.

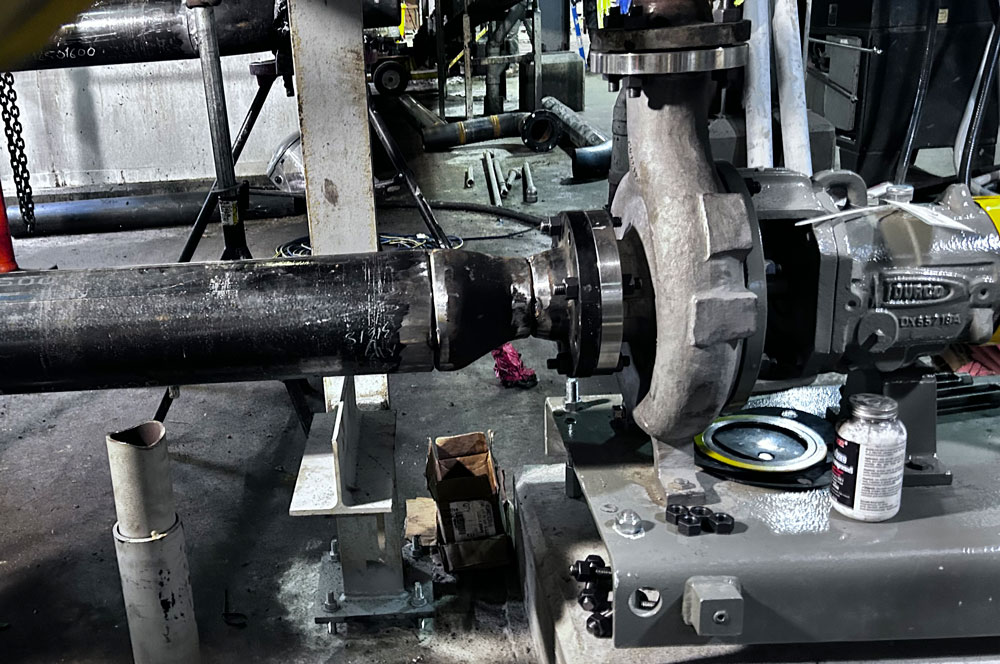

When machinery malfunctions or breaks down, trust our team to diagnose the issue, dismantle the parts, repair, or replace damaged components, and reassemble the machinery.

Our Red Seal Millwrights and registered apprentices are experienced in performing repairs and modifications to suit your needs.

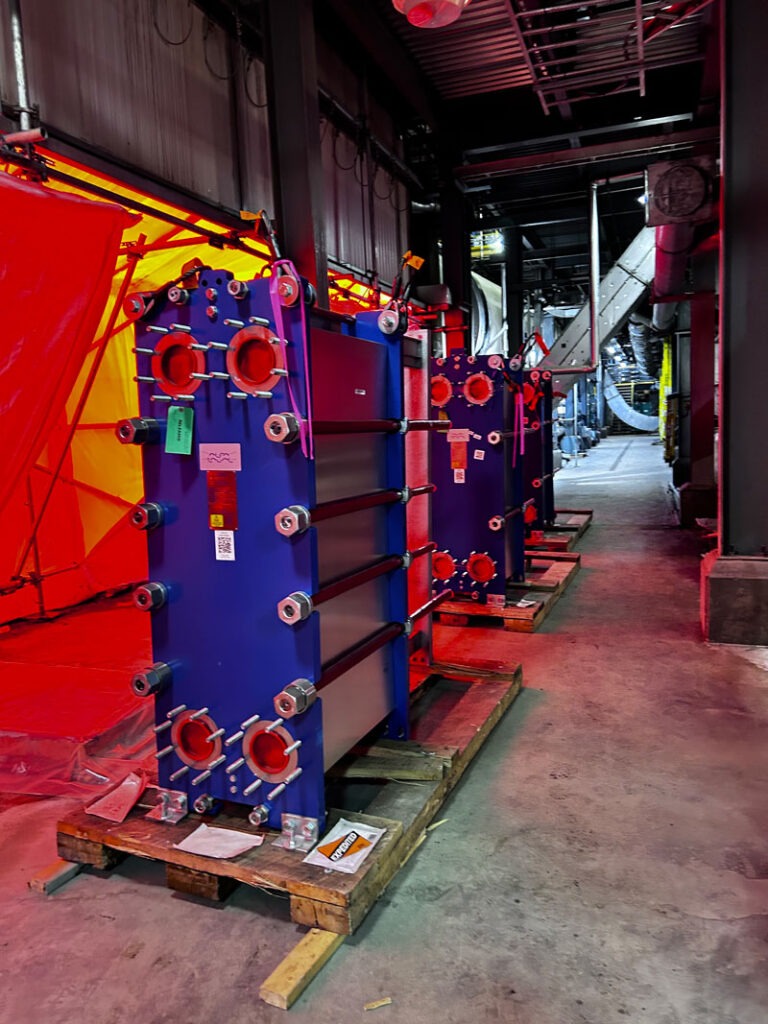

Our team of skilled Millwrights specializes in the installation and setup of new machinery and equipment across diverse industries. We ensure the precise assembly, alignment, and calibration of all components to guarantee optimal performance. From start to finish, we manage every aspect of the project, allowing you to focus on other critical areas of your business. Trust us to handle all your concrete, electrical, mechanical, and millwright needs.

Our fabrication facility has on-staff welders and fabricators to provide the skills necessary for fabricating or repairing metal components of machinery.

Our Millwright team also comprise of CWB welders. With this knowledge and experience we can make sure that any repairs that may come up at any time during a repair can be handled immediately and efficiently. Our prefab shop also can fabricate anything off site that is needed to ensure ease of mind that everything is being handled.

With 45 years of experience, our Millwrights are skilled in aligning machinery components to ensure they function correctly and efficiently. This involves using precision tools to align shafts, gears, belts, and other components.

Our Millwright team is well versed in laser alignment and can install all your bases, soul plates, pumps, and motors with absolute accuracy, which reduces downtime and costs associated with it.

We are proficient in rigging techniques, using cranes and other lifting equipment to move heavy machinery safely.

We assist in relocating machinery within a facility or from one location to another. This involves dismantling, transporting, and reassembling, and calibrating the equipment.

Wescan understands the importance of using safety guarding around your equipment to keep your most valuable asset—your employee—safe from harm and to be certain that Workplace Safety and Health protocols are being followed. Our team can visit your site, do an assessment of your equipment, and together come up with a plan to get you to that next step.

We can supply Red Seal Millwrights and registered apprentices for any duration of time needed. Either temporary holiday relief or to help with long term manpower shortfalls.

Our Millwright team is exceptionally experienced at plant shutdown work and special projects in many different sectors that include, but are not limited to, Industrial Plants, Agriculture Facilities, Food Industry, Manufacturing Industry, Railroad, and Vehicle Manufacturing.

Our Vibration Analysis and Dynamic Balancing services are indispensable assets for various industries. Utilizing cutting-edge technology and a team of highly skilled technicians, we conduct a meticulous assessment of machinery vibrations. This enables us to pinpoint potential issues before they escalate, ensuring the uninterrupted operation of your critical assets.

Through our precise Dynamic Balancing services, we guarantee optimal efficiency for your rotating equipment. This process not only reduces wear and tear but also extends the lifespan of your critical assets. Our on-site services minimize downtime, enhancing both productivity and safety. Trust us to provide real-time insights and solutions, safeguarding your equipment and operations while maximizing your bottom line in challenging field environments.

Our Route-Based Vibration Analysis serves as a predictive maintenance technique for assessing and monitoring the condition of rotating machinery and equipment. This involves periodic data collection at specific locations or “routes” within your facility. By detecting and diagnosing vibration-related issues before they escalate, we help you avoid significant failures and costly downtime. This approach prioritizes preventive measures, contributing to the overall reliability of your machinery.

1049 Logan Avenue, Winnipeg, R3E 1P6 Canada

Copyright © 2025 Wescan Construction Services. All Rights Reserved.