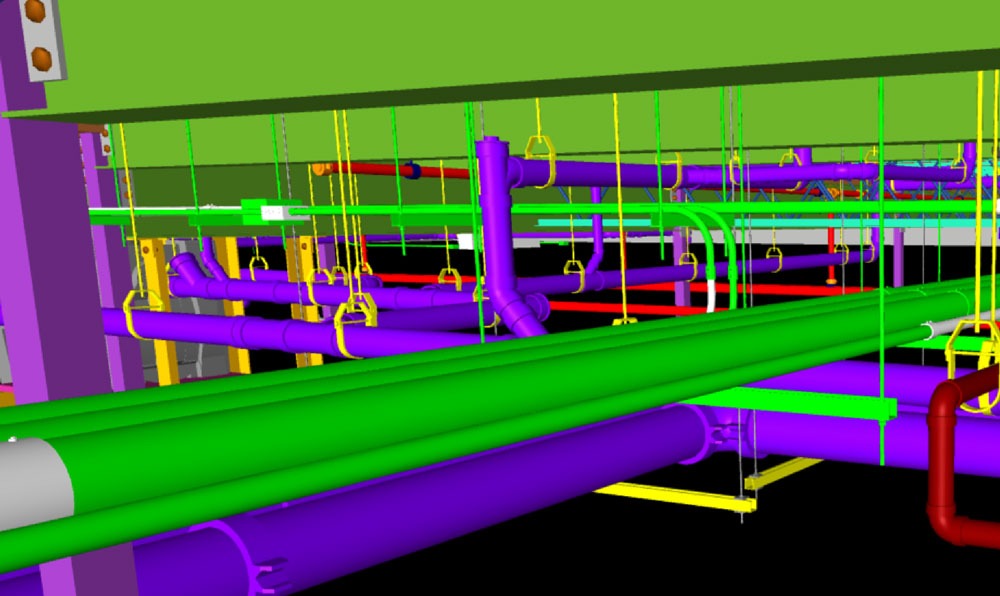

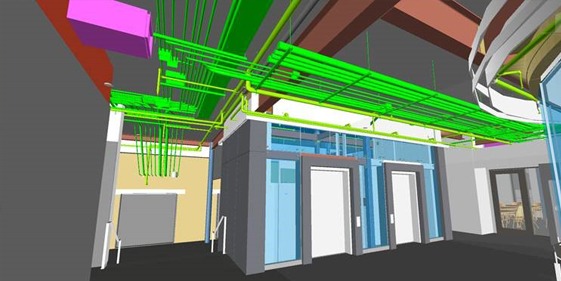

From Mechanical & Electrical Construction and Pre-Fabrication to General Pre-fabrication of structural pipe supports and hanger systems, Wescan is an industry leader with innovative processes and a quality-driven focus. Using state-of-the-art technology and Building Information Modeling (BIM), our design teams create customized planning and pre-fabrication programs for each project based on the unique requirements and logistics for each site.

Pre-fabrication helps to improve the quality and accuracy of the materials being used, as they are assembled in a controlled environment with a high level of accuracy and precision. This can help to reduce waste, save time, and improve the overall efficiency of the construction process.

By bringing construction into our shop environment, we can carefully manage every step of the fabrication process. This includes material selection, cutting, welding, and assembly, among other processes. We are able to closely monitor each of these processes to ensure that they meet our high standards for quality and consistency.

By taking the work off-site and pre-fabricating materials, we reduce waste, cut down on transportation emissions, and save energy. By embracing the principles of sustainability through pre-fabrication, we are able to create projects that are not only cost-effective and efficient, but also environmentally responsible.

Taking work off-site and pre-fabricating materials allows us to minimize disruption of other trades, reduce logistics issues with deliveries, and minimize the space required for material storage on-site.

Pre-fabrication also provides increased security and safety for our construction projects. By reducing on-site work, we minimize the risks associated with weather conditions and theft; With the benefit of overhead cranes and specialized equipment, we produce assemblies to the highest standards, all in a safer and more secure work environment that benefits everyone involved in the project.

Using Revit, our design and project teams work closely together on each BIM project to model all systems in 3D for fabrication and coordination purposes. By optimizing innovative technology and collaborative communication with all team members, Wescan can meet the constructability requirements, view any clashes, and help deliver an on-time, on-budget and within-scope project. Our approach includes:

Integrated Project Delivery involves all stakeholders in the construction process to streamline projects and improve outcomes. It reduces project management costs and eliminates the need for multiple contractors and their overheads. It also ensures coordination between mechanical and electrical systems on and off-site, resulting in fewer conflicts and delays.

Integrated Project Delivery offers improved value engineering solutions, improves safety, and reduces subcontracting by providing shared services and equipment on-site. It also streamlines procurement, resulting in cost savings by eliminating some middlemen and directly purchasing from suppliers. Additionally, it ensures effective handover by integrating O&M manuals and commissioning.

Overall, Integrated Project Delivery is a collaborative approach that ensures all stakeholders are involved in the project delivery process and coordinates all aspects of the project efficiently.

We offer a comprehensive set of services that enable our customers to enjoy a seamless delivery experience. Our services include:

We provide Design Assistance in various areas such as mechanical, electrical, communications, security, welding, and structural steel. We work with our customers to understand their requirements and offer design solutions that meet their needs.

We take a collaborative and value-based approach to engineering design support. Our early input into the design phase allows for realistic results, and we participate in regular design workshops to ensure timely cost estimates and schedule updates. We also offer in-house value engineering to optimize our customers’ projects.

Our Value Engineering Services focus on cost reduction (both initial and life-cycle costs), constructability, functionality, sustainability, maintainability, equipment (non-proprietary, local), leading-edge money-saving product implementation, practical off-site construction fabrication input, construction staging, and site management planning.

Pre-planning is essential for high-quality project delivery. Our dedicated full-time pre-planning department uses the latest technology to aid in pre-fabrication and construction, including Building Information Modelling (BIM). We update our Risk and Opportunity Register and develop our plan for high-quality performance execution.

We have a 38,000 square foot fabrication facility that enables us to fabricate mechanical, electrical, and steel/misc. metals assemblies. Our controlled environment ensures a high-quality product, as well as safer production for both trades and customers.

Electrical and Mechanical testing and commissioning are crucial stages in our fabrication processes. Commissioning is a systematic process that involves system testing, verification, integration, and functionality, as well as the documentation of all system components. We ensure that our customers’ systems are thoroughly tested and commissioned to ensure reliable and efficient operation.

1049 Logan Avenue, Winnipeg, R3E 1P6 Canada

Copyright © 2025 Wescan Construction Services. All Rights Reserved.